In the vast universe of textile printing, each technique offers a world of possibilities, designed to suit different needs and projects. Direct to Film (DTF) printing, screen printing and sublimation are three of the most prominent methodologies, each with its own particularities, advantages and considerations. In this analysis, we will explore these techniques in detail, with special emphasis on how TUDTF.COM positions itself as an innovative solution to overcome the challenge of initial investment in DTF printing.

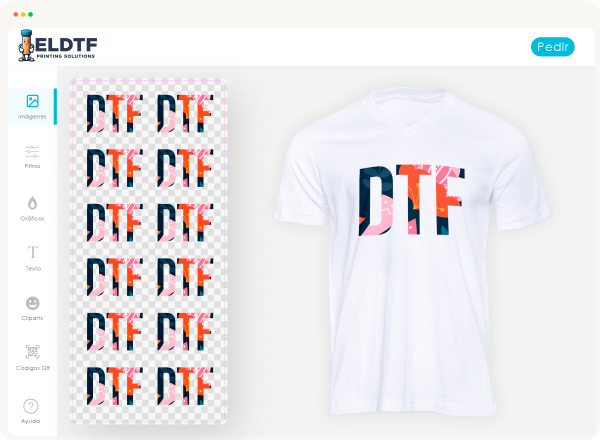

DTF Printing: Innovation and Versatility

DTF printing excels in its ability to print on a wide variety of fabrics, including cotton, polyester and blends, without requiring special pretreatment. This technique is recognized for its excellent color quality, fine details and adaptability to short runs, making it ideal for custom and niche projects.

The Initial Investment Challenge

One of the barriers to adopting DTF printing can be the initial investment required for the equipment. This is where TUDTF.COM makes the difference. By offering DTF printing services by the meter, TUDTF.COM eliminates the need for a large upfront investment, allowing designers, small businesses and entrepreneurs to access this state-of-the-art technology without the financial commitment of purchasing and maintaining their own equipment. This approach not only democratizes access to high-quality printing but also allows users to experiment with customized designs with unprecedented flexibility and efficiency.

As we dive into the vibrant world of textile printing, we discover three prominent techniques that have transformed the way designs come to life on fabric: Direct to Film (DTF) printing, screen printing and sublimation. Each method provides unique opportunities for creative expression, but also presents its own sets of advantages and challenges. In this material analysis.

Silkscreen Printing: Tradition and Economy for Volume

Screen printing, known for its durability and economic viability for large volumes, remains a favorite choice for mass orders. Its strength lies in its ability to produce vibrant and durable prints, especially on materials such as cotton, but much more limited when working with many colors at once.

Sublimation: Detail and Versatility in Synthetics

On the other hand, sublimation stands out for its exceptional image quality and durability on polyester fabrics. This technique is ideal for detailed designs and bright colors, integrating completely into the fabric for a touch-free finish.

| Feature | DTF (with TUDTF.COM) | Silk-screen printing | Sublimation |

|---|---|---|---|

| Compatible Fabrics | All, including cotton, polyester, and blends | Better in cotton | Polyester only |

| Color Quality | Excellent, with high fidelity and detail | Vibrant, ideal for solid designs | Exceptionally detailed, perfect for complex images |

| Durability | High | Very high, resistant to numerous washings | Integrated into the fabric, extremely durable |

| Initial Cost | Low with TUDTF.COM, no own equipment required | Requires investment in screens and inks | Specific printer and heat press required |

| Cost per Unit | Competitive in every way, ideal for short runs and customization | Economical in large volumes | Moderate, depending on size and complexity of design |

| Ideal For | Flexibility and customization without large initial investment | Large volumes and less complex designs | Detailed designs and customization in synthetic fabrics |

| Preparation and Production | Fast and flexible, perfect for agile responses to the marketplace | Longer setup time, but fast once configured | Fast, direct to fabric, no drying required |

Conclusion